Practical guide of the temperature switch between nitrogen and helium¶

Consult beamline scientist before changing any temperatures¶

Performing experiment at room temperature : 240K --> 300K

- Step 1 : Make sure N2 valve is open and He is closed

- Step 2: FOURC >

roomT(# set temperature to 1st and 2nd controller to 130K and 110K) - Step 3 : Make sure in the controller 1 (Input A) and B (input C), it will to reach the temperature 96K and 110K .

- Step 4: FOURC >

flow_set 6( # talk to Staff Scientist for the desired flow rate of your experimental setup) - Step 5 : FOURC >

te 300(# set the temperature to 300K)

Cooling temperature of cryocooler with N2 : room temperature 240K --> 95K

- Step 1 : Open the N2 valve and close He valve

- Step 2 : FOURC >

prepnitrogen(# it will setup the temperature in the Lakeshore controller) - Step 3 : FOURC >

te 170(# lowering temperature to 170K) - Step 4: FOURC >

flow_set 9( # talk to Staff Scientist for the desired flow rate of your experimental setup)

Please use Helium sensibly!

Cooling temperature of cryocooler with He : 85K --> 13K (also if you want only room temperature 300K and 15K) (change to N2 to He flow)

- Step 1 : FOURC >

te 230(# it will setup the temperature in the Lakeshore controller) If the ice did not melt - Step 2 : FOURC >

flow_set 9 - Step 3 : Turn on the He valve and close N2 valve together

- Step 4 : FOURC >

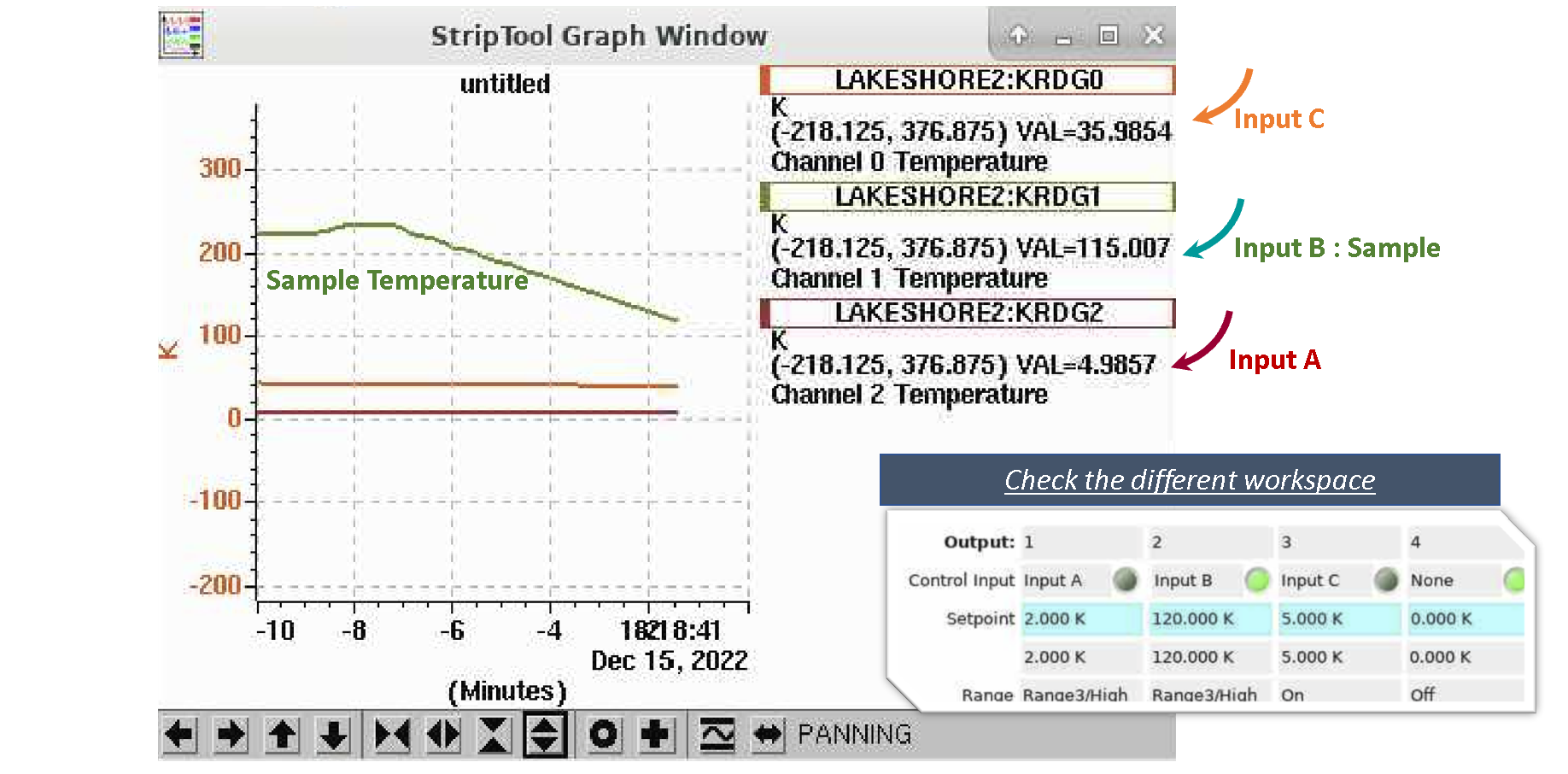

runninghelium(# it will setup the temperature in the Lakeshore controller) - Step 5 : Wait for base temperature (Input A ~5K Input C ~36K) to stabilize (look at the plot below)

- Step 6 : FOURC >

te 14(# lowering temperature to 14K or others) - Step 7: FOURC >

spin_xtal_phi(# rotate sample 360-->0 and 0-->360 degree in phi directions and you can STOP that by control C )

Heating temperature of cryocooler : 13K --> 85K (change to He to N2 flow)

- Step 1 : FOURC >

prepnitrogen(# it will setup the temperature setpoints 87K and 83K in the Lakeshore controller Input A and input C) - Step 2 : FOURC >

te 180(# it will setup the desired sample temperature; here sample temperature is 180 K) - Step 4 : Make sure all the temperature is above 80 K (Input A 86 K, Input B (sample temperature) and Input C 83K in PLD controller)

Danger

N2 in all conditions should be above 80K (N2 (channel A, B, C) --> all temperature-->80K)

- Step 3 : Once Input A, B and C are above 80K, then open the N2 valve and close He valve together

- Step 4 : FOURC >

te 100(# increase temperature to 100K or any other desired temperature)

Room Temperature to base : 300K --> 15K (change N2 to He flow)

- Step 1 : FOURC >

prepnitrogen(# it will setup the temperature in the Lakeshore controller channel A = 85K and channel B = 83K) - Step 2 : FOURC > Wait until the temperature of the channel A and C is stabilize to 85K and 83K

- Step 3 : FOURC >

te 230(# it will setup the temperature in the Lakeshore controller) - Step 4 : FOURC >

flow_set 9 - Step 5: you need to wait until the temperature of the sample is 230K (it might be lower)

- Step 6 : Turn on the He valve and close N2 valve together

- Step 7 : FOURC >

runninghelium(# it will setup the temperature in the Lakeshore controller) - Step 8 : Wait for base temperature (Input A ~5K Input C ~41K) to stabilize (look at the plot below)

- Step 9 : FOURC >

te 15(# lowering temperature to 15K or others) - Step 10: FOURC >

spin_xtal_phi(# rotate sample 360-->0 and 0-->360 degree in phi directions and you can STOP that by control C )

Heating temperature of cryocooler : 13K --> 300K (change to He to N2 flow)

- Step 1 : FOURC >

prepnitrogen(# it will setup the temperature setpoints 85K and 83K in the Lakeshore controller Input A and input C) - Step 2 : FOURC >

te 230(# it will setup the desired sample temperature; here sample temperature is 220 K) - Step 3 : Make sure all the temperature is above 80 K (Input A 87 K, Input B (sample temperature) and Input C 83K in PLD controller)

Danger

N2 in all conditions should be above 80K (N2 (channel A, B, C) --> all temperature-->80K)

- Step 4 : Turn on the N2 valve and close He valve together

- Step 5 : FOURC >

roomT(# it will setup the temperature setpoints 130K and 110K in the Lakeshore controller Input A and input C and it will to reach the temperature 97K and 110K.) - Step 6 : FOURC >

flow_set 6(# increase temperature to 100K or any other desired temperature) - Step 7 : FOURC >

te 300(# increase temperature to 100K or any other desired temperature)

Performing experiment above room temperature : 300K --> 500K

- Step 1 : Make sure N2 valve is open and He is closed

- Step 2: FOURC >

prephighT(# increase temperature to 1st and 2nd controller to 235K and 220K) - Step 3 : FOURC >

flow_set 6 - Step 4 : Make sure in the controller 1 (Input A: 103K and B input C: 150K), it will to reach that temperature and stabilize.

- Step 5 : FOURC >

te 480(# increase temperature to 400K)

Note: Above 480K, it took long time to go 498K

Performing experiment from high temperature to room temperature : 500K --> 300K

- Step 1 : Make sure N2 valve is open and He is closed

- Step 2: FOURC >

prepnitrogen(# increase temperature to 1st and 2nd controller to 85K and 83K) - Step 3 : Make sure in the controller Input A and Input C, it will to reach the temperature 85K and 83K.

- Step 4 : FOURC >

te 300(# increase temperature to 300K)

Turn off the temperature controller

- Step 1 : Heat the temperature 300K, 300K, 300K

- Step 2 : close the compressor

- Step 3 : Wait until go to the required temperature

- Step 4 : Close the valve

Problem : Ice formation at low temperature¶

- a) Figure 1 : Check the distance between the cryo-stream and sample (it should be as close as possible)

- b) Figure 2 : Continuously rotate the phi

umv phi 360; umv phi 0at low temperature -

c) Figure 3 : Check the gas flow and if needed talk to the staff scientist

FOURC> flow_set <number>FOURC> flow_get

Problem : High temperature issues¶

- a) Figure 3 : Check the gas flow and if needed talk to the staff scientist

Problem : Accidentally closed the temperature controller¶

- Step 1 : Open terminal and type

StripTool -

Step 2 : Connect to epics PVs

-

Need to connect to epics PVs that you want to monitor

- LAKESHORE2:KRDG0

- LAKESHORE2:KRDG1

- LAKESHORE2:KRDG2

-

y-axis click “Modify” button (same y axis for all the curves)

Emergency proceduce if the temperature controller fails or Sudden power failure at beamline¶

Talk to Beamline Scientist or operators --- DONOT TRY THIS WITHOUT ASKING

- If the your setup is in nitrogen condition (300K - 80K) and suddenly temperature is dropiing drastically and you don't have controls

- Switch the valve Nitrogen to Helium

-

Closed the compressor

-

Change the EPIC PVs range